Innovative Engineering

I work across Systems Engineering, Hardware & Test Engineering, R&D, and Product Management — always with the principles of Physics in my mind. This breadth lets me bring people and disciplines together, ensuring great ideas don’t stay siloed.

Since 2025, I work at navel robotics.

Developing a "robitic beeing you want to be with"

Role: Systems Engineer

Making Navel ready for market

Video by navel robotics (https://navelrobotics.com/en/navel-the-new-empathy-robot-for-good-care/)

About Navel

Navel is a social, empathic robot deployed in care homes since October 2023 as a pre‑series model. It specializes in cognitive and emotional activation—providing companionship, initiating conversations, and supporting dementia care—thus relieving overworked staff facing emotional exhaustion and lack of breaks . Powered by large language models (like GPT), Navel detects social cues via vision and audio, enabling empathetic responses (“social superpowers”) such as endless patience and unconditional positive attention. Its architecture is privacy‑compliant: image data are processed locally and deleted in milliseconds, while AI processing uses GDPR‑compliant European servers.

Current Challenges

Staff shortage: Caregivers are frequently emotionally exhausted and understaffed .

System solution: Automate emotional activation using Navel to increase interaction frequency and lighten caregiver burden.

Regulatory hurdles (e.g., CE certification, AI Act, Medical Device Regulation): The robot must meet safety and data protection standards.

System solution: Prioritize modular architecture with certified components and embedded data protection, enabling compliant rapid iteration for market deployment.

Robust autonomous behavior (e.g., navigation, context awareness): Navel sometimes misrecognizes faces or cannot approach users independently .

System solution: Enhance computer vision, context awareness, and autonomous decision-making algorithms for smoother real-world interaction.

Testing Daimler's Infotainment Systems

Role: Test Engineer (including System & Hardware Engineer)

Scaling up a highly automated "Testfarm"

Challenge

Test engineers at Mbition (Berlin) need to find the error in 8 billion lines of code—every day—and it is not very efficient to flash each day’s batch onto a car. That’s why cars are simulated by testbenches. To optimize testbench efficiency, Accenture’s Industry X (formerly umlaut) built a “Managed Test Target Farm” (MTTF), empowering it with tools such as automatic daily flashing and automated testing. The challenge was to integrate the hardware into the test landscape at Mbition and to avoid misuse by the test engineers.

My Role

As test engineer and IT support for the managed test target farm (MTTF), I led a transformative change plan to maximize system availability, ensuring standardized and rugged hardware design, including unique connector design to eliminate missuse. I onboarded Mbition employees to the new UX with an informative flyer, and implemented a JIRA-based ticket system for optimized support requests.

This is how I see myself prototyping (source: adobe stock)

Developing a rugged Power Generation System

Roles: Procedure & Documentation Manager, System Engineer (including Hardware & Electric Engineer, EMI Engineer, Test Engineer)

From Prototype to a Production Run of 1,000

Challenge

Developing the electric propulsion system for the Thales Hawkei, a high-stakes $1.3 billion defense project by Thales Australia. This involved power electronics, a high-performance starter/generator, and advanced cabling solutions, all engineered to meet the extreme demands of military deployment. The project also required in-house manufacturing of 1,000 units, ensuring production control, quality assurance, and seamless integration into the vehicle platform.

My Role

As Process and Documentation Manager and System Engineer, I played a key role in the TRL 6 to TRL 9 phases of the Electric Propulsion System (Starter/Generator with PMU). I developed and implemented structured processes to eliminate requirement gaps, ensuring that all project documentation and deliverables were completed on time and met the necessary quality standards.

Leading the EMI engineering department, I drove R&D efforts, EMI filter design, and certification under MIL-STD-461, securing compliance for military use. As a System Engineer, I focused on functional safety development, spearheading the first integration of the ISO 26262 process landscape within the company.

As Process and Documentation Manager, I established and optimized workflows to improve efficiency and ensure full traceability of requirements. I redesigned the requirements database (DOORS), streamlining development for engineers and providing a solid foundation for Product Lifecycle Management (PLM).

Building up an EMI Measuring Chamber

Roles: Lead Design Engineer, Project Manager

Ensuring Electro-Magnetic Compliance (EMC) within product development

State-of-the-art EMI-Lab for certification of electric components, such as in cars and satellites (source: "Testing with Radio Waves" by NASA/Chris Gunn via https://www.flickr.com/photos/nasawebbtelescope/50275065832/in/photostream/)

Challenge

Ensuring accurate EMI measurements for product development of electric propulsion systems. The EMI lab needed to be a faraday cage with interfaces to power, cool and control an electric propulsion system inside.

My Role

My role was to engineer an EMI measuring chamber tailored for this project, focusing on precise electromagnetic compatibility assessments. My work encompassed designing and constructing a robust chamber, adhering to EMI engineering standards (MIL-STD-461), and integrating advanced measuring equipment, all for 5% of the standard price for a common measuring chamber (such as IABG) with 95% functionality. The chamber enabled reliable and accurate EMI testing, ensuring compliance and enhancing the overall quality of the propulsion system.

Interferometric detection of cell activity on periodic nano structures

Role: Research & Development (master's thesis in physics)

Growing human cancer cells on periodic gold nanostructures

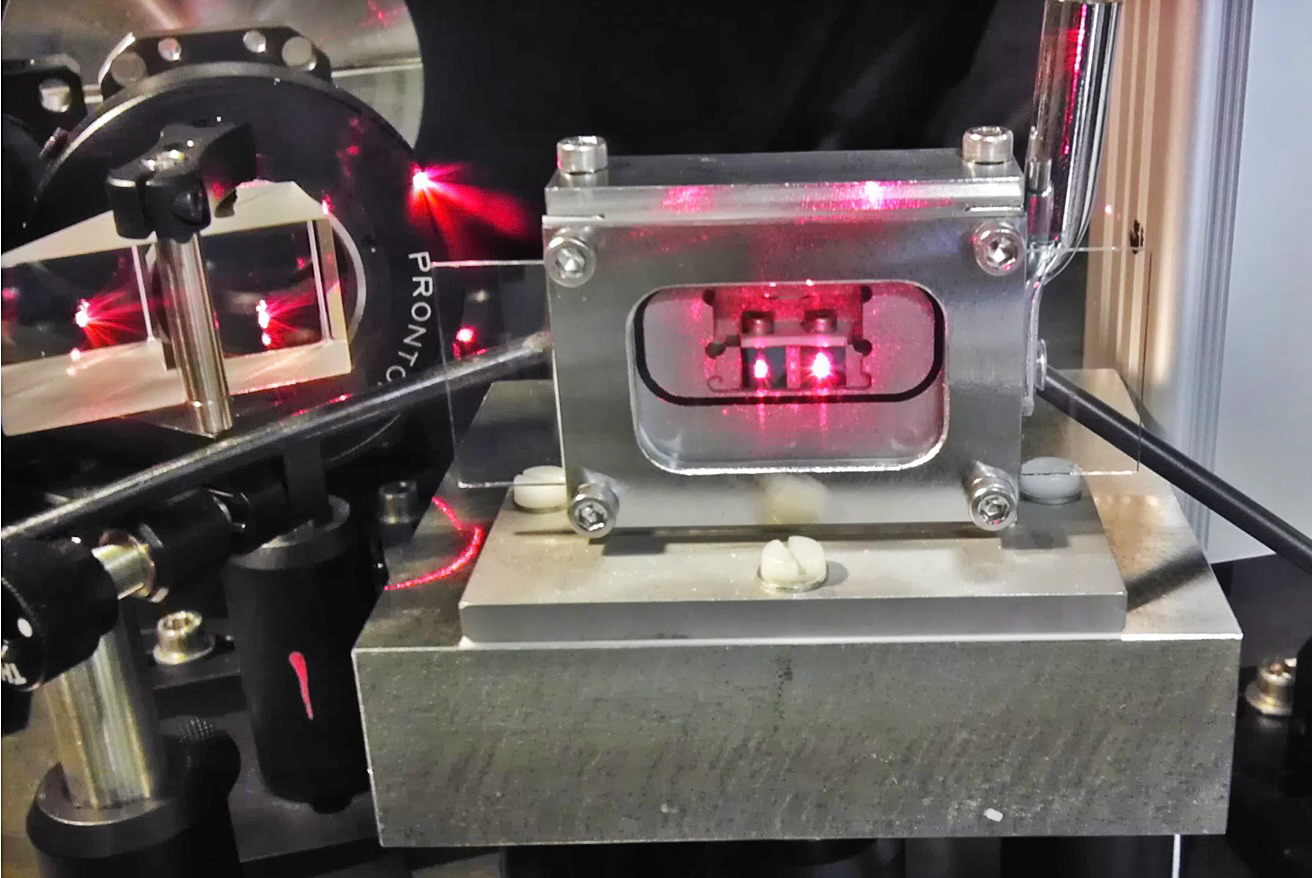

Master's Thesis: Building a Laser Microscope to grow cells and observe their vitality (LMU Munich, 2014)

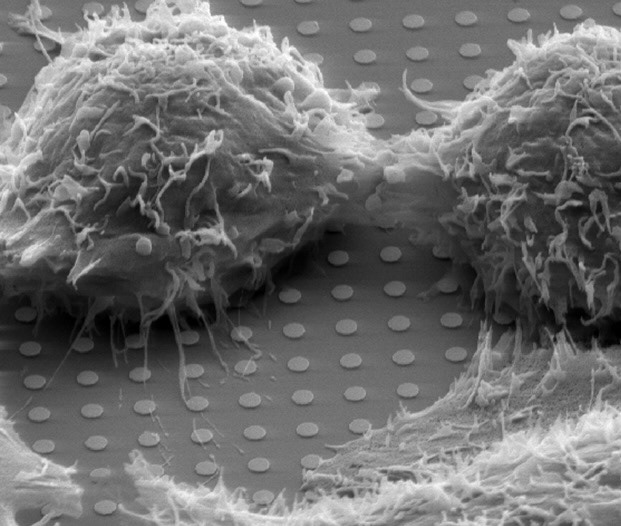

Master's Thesis: Own image of a human cancer cell caught in the moment of cell devision (REM image, 5000x magnitude, LMU Munich, 2014)

Challenge

Proving a correlation between the Debye-Waller model in solid-state physics and a perturbation model in biophysics to develop a cost-efficient, lens-free microscopic method for measuring cell activity and performing drug screening.

Approach

Theoretical derivation observed nanostructures under cells using a standard brightfield high-resolution microscope to track the "lensing effect" of cells, with A549 human skin cancer cells as test subjects. Pre-experimental data showed a clear correlation between cell activity and structure displacement, translated using the Debye-Waller model into reciprocal space to measure perturbation intensity on the main Bragg-maxima. The experimental setup included creating a "Bragg-Sky" with nanostructures and measuring the intensity of the second main maxima. This involved selecting appropriate CCD camera sensors, constructing a specialized probe chamber for cell growth, and cultivating A549 cells on SiO2 and gold chips. Cells were observed optically to ensure health, and different confluence levels were used to measure the light intensity correlation of the second Bragg maximum, proving the Debye-Waller model's application to biological matter.

Results

The perturbation of Bragg maxima was directly measurable by light intensity, correlating to cell density on nanostructures. These groundbreaking results led to further experiments with cells and bacteria, culminating in the formation of the startup Phio by my former colleague and supervisor Philipp Paulitschke.